HERE’S THE SKINNY ON LEATHER THICKNESS:

Leather thickness has always been an area of concern in the upholstery world, especially in the aircraft industry. Specific requirements for weight have even been formally established in leather supply contracts.

However, we want you to know, thinner isn’t necessarily better.

RISK

When targeting weight savings, the risk of what is sacrificed in strength must be considered. Leather’s strength is directly related to the center section of the structure, known as the corium. This structure is created by tiny fibrous strands that are twisted together into bundles. This fiber network forms an untold number of inter-locks which result in leather’s very high tensile strength. The thicker the leather, the more substance you have…the more interlocks…the result is greater strength. Therefore, as you reduce substance (thickness) you naturally reduce strength. Splitting (skiving) completed leather is a process that is often used to reduce thickness. The skiving process actually cuts the interlocked fibers of the corium and severely weakens the overall strength of the structure. Skived leather should never be used in contact/seating areas of upholstery.

QUALITY

As you may recall from a previous bulletin, one way to minimize the visibility of veins is to maintain a slightly thicker substance in the hides. Thinner leather shows more veins and vein detail.

FIRE RESISTANCE

Leather in itself is not a readily burnable material. The thicker the leather, the better its natural flame resistance properties. Much of leather’s propensity to burn depends on the dyeing and finishing processes. Fire resistance treatments are added to the leather substance to combat these processes. A thinner leather will not absorb as much fire-resistant treatment as a thicker leather will, which can lead to a negative influence on the flammability properties of the leather. Townsend Leather products are produced at the optimum thickness of 1.0-1.2 mm to give strength, softness, and workability. How leather thickness is measured: Hides are processed to make a uniform thickness. However, each animal is different and there is always a slight thickness variation throughout the hide. This is why leathers are typically sold with a range of thicknesses. Leather thickness is measured in millimeters using a gauge.

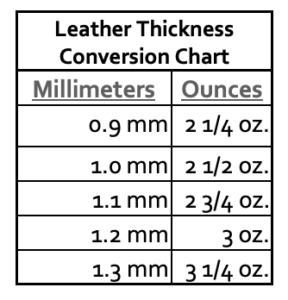

Thickness can also be specified in terms of weight with one ounce equal to 1/64 inch thickness.

If you know the leather thickness and the ounce conversion (see chart, below), you can easily calculate the weight per square foot using the following formula:

mm = 2.5 ounces/sqft

2.5 ounces/sqft x 55 sqft = 137.5 ounces

137.5 ounces divides by 16 oz/lb = 8.6 lbs / hide

Remember that thickness will vary within a hide and therefore, the weight will also vary. While this formula is very accurate, it will not always be exact because of the natural variations in thickness.